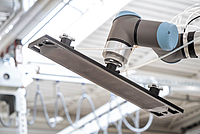

In the "esspresso" research project, the ZBT and its project partners are developing a low-temperature pressing process (NT pressing) for the production of large-area, thin graphite bipolar plates. The NT pressing process is intended to meet the perspective high demand for bipolar plates for fuel cell systems in heavy-duty applications through a short cycle time with simultaneously high component quality and thus further support the market launch of fuel cell trucks or buses.

The focus of the project is on the development of the pressing process in close connection with the associated tooling system for industrial scale and the graphite compound material optimised for the process. The aim is to enable the process-safe, large-scale production of graphite-polymer bipolar plates using NT pressing. A cycle time reduction compared to existing manufacturing processes is to be realised by the isothermal pressing process, the simultaneous pressing of several bipolar half-plates as well as the optimisation of the tool system and the pressing parameters.

The energy transition will depend, among other things, on the rapid scaling of the production of graphite bipolar plates. The "esspresso" project is really stepping up the pace here.

Funding Organisation: Federal Ministry of Economics and Climate Protection

Funding period: 1 Jan 2022 to 31 Dec 2024

Funding code: 03EN5020

Project partner:

- DORST Technologies GmbH & Co. KG

- Ensinger GmbH

- J. Schmalz GmbH

- TU Braunschweig, Institute for Machine Tools and Production Engineering

- Wirth Toolmaking GmbH

- ZBT - The Hydrogen and Fuel Cell Center

Department Fuel Cells and Stacks